4 Red Flags That Indicate You Need A Training Program

Written by Marilee Brewer

December 1, 2022

If you’re reading this article, it’s safe to say you care about your people, but you’ve got some problems. Whether you’re experiencing issues related to insufficient training, or you feel the pangs of not training at all— the following information will help you determine whether or not a healthy training program can aid your team in getting where you want to go.

What’s a training program?

First thing’s first: What is a training program? Hint—it’s more than a class here and there to keep you certified.

An employee training program is a planned sequence of activities to equip people with the tools they need to become better at their jobs and advance their career.

Employee training is often paired with employee development—an even broader term for the growth and encouragement of team members’ well-being. Employee training includes instructor-led training, mentoring, on-the-job training, eLearning, microlearning, and mobile learning.

The “people problem” in heavy construction

If you’re not aware of the “people problem”, here’s a quick overview.

There’s a labor shortage in construction.1 It’s so dire that some people are predicting the end of the industry. But let’s be real. Our society cannot survive without the industry that sustains life as we know it.

While some blame a lack of work ethic among younger generations, we’re learning the root of the problem lies in a disconnect between the industry and the world it serves.

With that brief reminder, let’s look at some of the troubles you may be experiencing and whether a training program might help.

RED FLAG #1

RED FLAG #1Quality of work

The quality of your work will make or break your company. That’s a given. So if quality suffers, so does your reputation. New people may make more mistakes, but if you spend significant time and money on rework, it may be time to look at training.

Workers—novice or veteran—who have not been properly trained on a skill will not be able to perform that skill well. Seems like a no-brainer, right? Kind of, but in construction, these skills haven’t traditionally been taught with any degree of formality. They’ve mostly just been passed down through the generations. But legacy construction families are a dying breed. An intentional training program is needed if you want to establish a consistent standard of work across your entire company.

In addition to rework, here are some reasons your team’s quality of work might suffer.

You’re not training on skill at all

If your team is only doing training when they have to, that’s a sign that something is amiss. Whether it’s obligatory OSHA, MSHA, or HAZMAT training, training-for-certs is not the type of training that will teach people the basics of how to do their daily job.

In addition, if safety is an intermittent class here and there and not an integral part of company culture, people aren’t likely to retain enough of the knowledge they are exposed to truly work safely.

It takes forever for basic laborers to become proficient

Does it take new team members too long to get up to speed? During the busy season, you bring in new people and start paying them, hoping they’ll catch on quickly. But they don’t catch on. Everyone around them is frustrated, no one else feels like they have time to spare, and the team struggles to stay on schedule.

Even if your new hires last through the discomfort of slowing their team down, they may have survived by learning shortcuts or figuring out how to do key tasks on their own—the wrong way.

You haven’t established standards of practice

If you haven’t articulated your company standards of practice, there’s no way you can teach them to others. A healthy training program helps you establish standardized methods of approach for everything your crew repeatedly does. It can include things like:

- Consistent orientation experience

- Basic formal training before a new task is performed

- Widely accessible resources for the way the company does a specific task

If any of these are confusing, variable, or unknown at your company, that’s a red flag that you need a training program.

RED FLAG #2

RED FLAG #2Lack of engagement

Are your people glad to come to work? Is there a general sense of engagement? If you answered “no” to that question, it could be because of circumstances that stem from a big red flag: a lack of engagement among your team. According to Gold Rush’s Dave Turin, if you have someone who isn’t following the rules, won’t engage, and doesn’t want to be a team member, it will make or break your team every single time.

Check out these scenarios to see if any of them sound familiar.

You train infrequently

While everyone likes a break from the field and office, training that occurs only once or twice a year can be seen as more of a “day off” than a learning experience. Any training that takes place so seldom is bound to be forgotten. It ends up being a waste of resources instead of an investment.

No one remembers anything from training

Another version of training that doesn’t quite stick are those long days spent in stuffy conference rooms. Everyone in the whole company attends, it takes three days, and after the week is over, no one ever thinks about it again. Some call it “death by PowerPoint.”2 There’s no conversation happening, the training is just being thrown at them.

If this scenario resembles what your company does, it’s a red flag. Whatever relief you might experience from “getting the training done” is bound to be short-lived if it costs you unengaged employees and high turnover.

You have to take people away from work to a central location to train

While this may be the only option, it can be disruptive for people to be taken out of context, exposed to new information, then expected to apply those ideas in their day-to-day work.

When people are tired, hungry, or bored, they tend to disengage. When important training is done far from the jobsite by PowerPoint, you risk a disengaged team. And a disengaged team member is more likely to search for greener pastures.

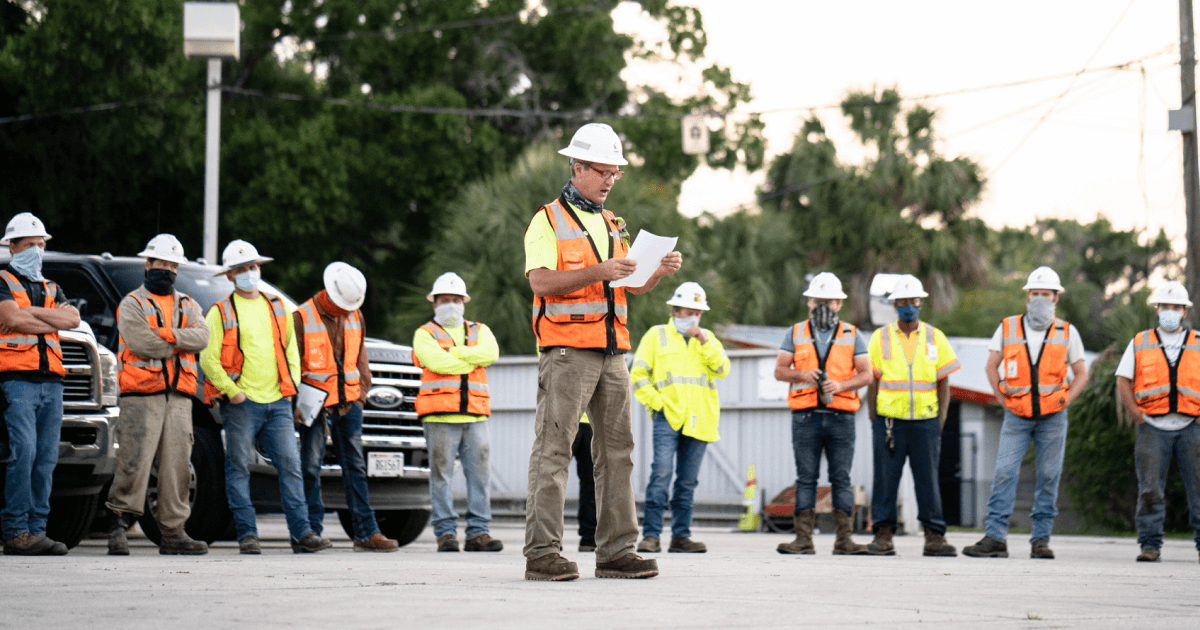

Toolbox talks are one-sided

Toolbox talks shouldn’t be presentations, they should be more like directed conversations. If your JSA’s, morning minutes, or toolbox talks are one-sided, where no one engages but the person talking, that’s a sign of a training problem. If your toolbox talks are boring and monotonous, employees may be disengaging. And bored, disengaged employees aren’t a good thing.

Every group conversation should be an opportunity to lead, encourage, and build up your teams. If people feel they matter and are listened to, they are much more likely to participate in the conversation. A training program can help you make that happen.

RED FLAG #3

RED FLAG #3Poor communication

We all know communication is hugely important for a successful team. But not everyone realizes that communication is a skill that can be learned.

With a good training program, communication should be interwoven into every lesson and, sometimes, directly addressed. Take note of that if you’re experiencing the following communication-related issues.

Messages don’t get from leaders to laborers

Is the trickle-down effect dammed up somewhere? If you can’t communicate a message to your leadership team with the full assurance the message will reach every employee, that’s a training-related communication problem that can put your whole team at risk.

Field leaders don’t know how to teach

For some field guys, it’s easier to show than tell. But people need more than a silent demo to understand new ideas. With a training program, your field leaders can learn communication skills, down to the exact words they can say, to help them become better teachers.

You’re out of touch with what’s going on in your company

You appreciate every employee and trust them to do their jobs. But are you too hands-off?

Even as someone with a lot of responsibility, it’s important that you know what’s going on with your team. Without communication between departments and areas, you may have no idea how employees are trained, much less what the experience of working at your company is like for others.

RED FLAG #4

RED FLAG #4Lackluster leadership

Last but certainly not least, weak leadership is one of the most insidious problems that no training, or poor training, can produce.

Look at two possible situations that may be contributing to poor leadership at your company.

Leaders don’t know where they’re going

There’s a lot of buzz about whether leadership is innate or learned,2 but the consensus is that it’s most assuredly something people can get better at. But if your leaders don’t have a path marked out for them through good training, how will they be able to point the way for others?

Negativity comes from above

Of course, you’ve never observed any conflict between experienced workers and new hires. But on the off chance that you have, it could be a problem with your field leadership. If you have people in leadership positions with a chip on their shoulder, suffering burnout, or going through things at home, the effect on the rest of your team can be immediate and severe. Leaders have the responsibility to set an example for their teams.

While training can’t resolve every problem, a good training program will allow those willing to learn a new, more effective leadership style. Old dogs can learn new tricks.

Seeing red? It’s time to evaluate your issues

Remember, many people (inside and outside of construction) don’t know about or understand the industry. If they have heard of the trades, their view is probably outdated. For instance, many parents worry that construction is too unsafe, not well-respected, or underpaid, so they steer their kids toward college instead.

Companies, especially “old-school” players, are focused solely on the work itself at the cost of their team. They don’t realize how important doing work that matters is to people. As a result, they don’t tell their real story, and no one talks about the mission. While “mission” may sound like a buzzword, it is HUGELY important to people that their work has meaning.3

On some teams, no one has ever learned a thing about leading others, and they don’t know how to communicate. Foremen bark orders, margins are extremely tight, and morale is low. And when morale is low, people disengage, even to the point of quitting.

Disengaged workers reinforce the false impression that the industry is “dangerous,” “low-brow,” “indigent,” or other negatives—and the cycle continues.

Training as a catalyst for big change

Naysayers may insist the workers are to blame, but many construction leaders realize the ball is in their court, and training will give them the momentum they need to get it rolling.

While training isn’t a miracle pill for the construction industry, it is a huge step in the right direction.

If you’re experiencing any of these red flags, it’s a good indicator that action is required regarding how you are training. A bad training program can be just as much of a hindrance to success as no training program at all.

Conclusion

Now you’ve read a little about the construction industry's dilemma. You may even be tired of hearing about the problem. And we’re tired of mere talk, too. That’s why we’ve been studying the situation to create training that will bridge the gap between people and the trades that need them.

You can use this discussion of red flags to identify your company’s most pressing issues and create solutions. Training is a big one for most people, and the BuildWitt team is committed to developing excellent, engaging training tools to help our entire industry survive into the next century and thrive.

More about

Sand Cone Test for In-Place Density Testing Soil by Sieve - Minus #40 5 Heavy Equipment Maintenance TipsMeet the Expert

Marilee Brewer

Marilee Brewer's philosophy on heavy civil construction is that everything—even the Bingham Canyon Mine and the Willis Tower—starts with ideas put into words. An avid writer and researcher, Marilee brings inspiration, storytelling, and human candor to Dirt World information. Her writing focuses on providing content that enhances user experience, improves engagement, and ultimately increases revenue. A trained Linguist and social media storyteller, ask her for story and social media writing tips.