BuildWitt: A Not So Brief History (PART 9)

The Raillroad, Pile Driving, and Hot Dumps

Welcome back to my best, yet likely inaccurate, recollection of the history of BuildWitt!

In case you missed PART 8, I discussed my physics failure, estimating competition humiliation, and quitting.

Sweet relief… Two years of engineering school down! Time to relax for the summer. Trick! I was in for the most miserable few months of my life…

WARNING—lots of construction and engineering speak incoming!

Onboarding

I reported to Skanska's Phoenix Civil HQ a few days after finals.

Skanska is a top-ten global contractor by volume and has built iconic projects like the UN headquarters, LaGuardia Airport, and the LA Metro.

While I expected a sleek steel building clad in floor-to-ceiling energy-efficient glass, I found a job trailer in a tired industrial yard instead.

I took a piss test and haphazardly filled out my employment paperwork. Even though I employ 75 people today, I still couldn't tell you how to fill out a W2 correctly.

After checking the necessary boxes, I reported to the boss, Pat, to determine my assignment. He wasn't sure. There was another intern, and Skanska had several projects around the valley and abroad. But he did mention their upcoming railroad project.

I BADLY hoped for the railroad because it was unfamiliar and out of town. After working in Phoenix for a few summers, I was ready for new scenery. Careful what you wish for, as they say...

I kept myself occupied by reading through plans and handling admin work. I read the railroad project plans cover to cover. I had no idea what most of it meant, but I enjoyed figuring it out.

At the end of week one, I had my marching orders. I was off to Union Pacific Railroad!

Yuma

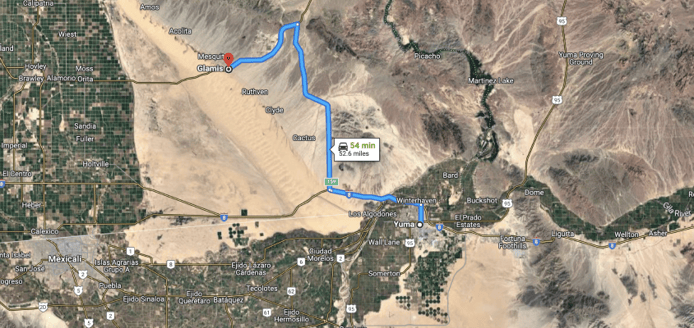

Our project was technically in California, but the closest civilization was an hour away in Yuma, Arizona.

Until this summer, my only exposure to Yuma was stopping at the gas station to break up the drive from Phoenix to San Diego as a child. With about 100,000 people, it's not a booming metropolis, but it does have a Chick Fil A (I had so many chicken tendies). Think mix between US-Mexico border town, farming community, and military base.

As "management," I received $125/day per diem on top of my already HUGE $15/hour pay. Everyone stayed in the local Best Western, where they offered us a $60/night rate. Not only did this mean I was ahead by $65 when I showed up every morning, but they also paid me mileage in my lil Toyota Camry to drive there and back.

We'd wake up around 2:30 to meet at the gas station at 3:00. Everyone fueled up daily—between the mileage to and around the site and idling our trucks to prevent heat exhaustion, we burned plenty of gas.

Then we'd hit the interstate, cross into California, and take the Ogilby Road exit. Our headlights were the only thing breaking the pitch-black night. Only us and the Coyotes were out in the desert at that hour.

The last paved leg of the drive was down the 78, past the Mesquite gold mine. I wanted nothing more than to see beyond the mountain of spoils. Little did I know I'd regularly visit large-scale mining operations only years later!

We'd hit Glamis, CA, and peel onto a dirt and sand road. Glamis, CA, is best known (the only thing it's known for) for its dunes. When the weather's good around the holidays, it's an off-road Mecca. But calling it a town is a dramatic overstatement—one shop called the Glamis Beach Store is only open during peak season. It was safe to say we'd missed the season...

After another fifteen minutes tearing down the dusty and unkept road, we reached our project headquarters, a small job trailer only a stone's throw from Union Pacific's Sunset Route. We'd fire up the generator just after 4:00 AM and do our paperwork before the craft showed up at 5:00.

The Railroad...

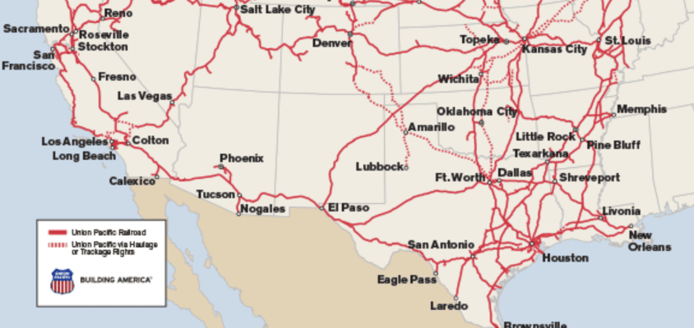

Yes, railroads are still a thing. Until recently, with the headlines about impending strikes and catastrophic derailments, few people thought about them. But in reality, much of our oil, grain, lumber, cars, chemicals, coal, and other goods travel the US by train. Since rail is far cheaper than trucks per ton per mile, it's the go-to shipping method for most of America's heavy cargo.

Class one railroads are essentially monopolies. Two railroads own the Western US—BNSF and Union Pacific. There are only a few complete routes connecting the West Coast with the East, and UP's Sunset Route, where we worked, was one.

With the enormous increase in demand for rail, UP invested billions in building a second complete mainline track alongside the legacy track from California to Texas. With an unbroken line in both directions, they could run trains east and west without stopping to allow others to pass.

By the time we arrived, the new track was done, with around 120 trains passing daily. But the old track needed work.

Our Scope of Work

The desert's usually dry, but when it rains, it pours. Flooding is common, and drainage under roads and railroads is critical for stability. The old track, built in the early 1900s, rested upon worn timber bridges that looked like I could've pushed them over, and I'm WEAK.

Enter team Skanska and me. Over six weeks, we'd replace four bridges with modern steel and concrete equivalents. How hard could it be?

First, the railroad's crews cut the track. Then, we'd swoop in to remove the ballast rock resting below the ties and demolish the wooden structure. Once cleaned up, survey would stake for the new abutments and piles.

Using a crawler crane, we'd drive 40' sticks of steel H-pile into the earth, but 40' wasn't enough to reach bearing capacity (enough friction to stay put as trains pounded them further for future decades). To give us another 40', welders affixed more steel onto the driven piles overnight.

We'd drive each home the next day, with every pile requiring a different depth to reach its resting place (more on this later). The welders returned the next night to cut each pile to its final elevation and weld the caps.

With the hard part done, we used a rough terrain crane to lift and set the precast concrete bridge deck sections. Our crews replaced the ballast, and the rail crews replaced the track.

Oh yeah… And the railroad shuts down for no one. While they shut our track down, they ran the other 24/7. We performed all work within 10' of fully-loaded freight trains. Fun? Think again… It's a mix of sheer terror and frustration.

Counting Blows

If only I'd experienced this lesson before the estimating competition revolving around pile driving… Damnit.

As I explained, steel H-pile connected every concrete bridge with the earth. We whacked them into the ground with a pile hammer supported by a crawler crane to install them.

Since I was only twenty with no relevant experience, they awarded me with the prestigious task of "blow counting."

To prove that we'd driven every pile far enough, we submitted paperwork proving the bearing capacity on each. To calculate the bearing capacity, we counted blows per foot and minute simultaneously.

The senior engineer showed me the ropes on one pile, and I was alone for the rest. No pressure… If we drove them too far, we'd waste heaps of money. And if we didn't drive them far enough? The bridge would settle over time, causing potential derailments. Neat!

I stood by as the pile crew wrestled the leads into position. Getting the leads right was almost everything… They guided every pile as the hammer whacked the top. If they were off, the entire pile and bridge would be off. Think of your fingers holding a nail.

This was the frequent scenario—they'd fight the leads for fifteen minutes. The flagger would come over the radio, "train coming fifteen minutes." They'd finally have the leads into position, ready for the hammer to fire, but then the train would barrel out of the distance like a desert mirage. They'd step back, letting the leads return to starting position, watch the train pass, then their wrestling match would restart.

Once the hammer began, it was deafening. I wore earplugs and earmuffs, and my ears would still ring at the end of the day. Hot oil rained down on everyone. *WHACK one WHACK two WHACK three.*

Schedule

The railroad stops for no one. They don't care about holidays, weekends, birthdays, or families. The work is paramount.

They'd allow us nine-day shutdowns, with seven days of "rest" in between. That meant we worked nearly 24/7 during the "on" days to finish the work. And our "off" days? Not for management… There was more paperwork, materials to order, and cleanup to finish before the next stint.

Being behind schedule wasn't an option. If we got behind, we'd work more. There was one bridge where we worked all day, worked all night, caught a few hours of sleep in our trucks, then worked all day again.

But I didn't mind the hours (usually around 70-80/week). I was making INSANE money, and Yuma sucked. It was either working to earn more money or sitting in my depressing hotel room. Easy choice.

HEAT

You "but it's a dry heat" people should spend a few days in Glamis in July. Most days were around 110 degrees, with some reaching 115-120. If we shut our trucks off, they could get 150+ degrees inside within an hour.

If we forgot to drink water for even half an hour, we were behind for the rest of the day. Dehydration followed us like a boogeyman, just waiting for complacency.

The most dangerous part of the job? Taking a dump… Everyone tried their best to hold it, but sometimes our digestive systems would get the best of us. Sitting in the portapotty at noon should've required its own JHA and buddy system.

Despite the brutality of the weather and task, no one complained. I loved the shared struggle. We knew how miserable the others were, but we were getting the job done anyway.

Social Life

Since I worked 7-9 days per stint, the title here is intentionally misleading—I had no social life.

I remember opening Instagram on a Sunday at 4 AM as I showed up for another shift only to see everyone back home living it up as "normal" 20-year-olds. A few of my friends worked, but none lived the railroad life. I guess I was living it up in a different way?

I'd occasionally drive home for two days off, which I almost wished didn't happen. It was a tease—a small taste of normalcy before returning for more misery.

All I had was the work… It's such an evil trap. You're away from home, so all you do is work. Because you work so much, you make great money. Then you go home and adjust your cost of living to your inflated income by buying mostly dumb shit (I didn't, thankfully). Even if you're off for a week, you're winding down from 24/7 work for a few days and mentally gearing up to do it all over again.

Thank God I only had a few months of it, and God bless anyone who does it today full-time. It's a necessary evil… Or is it? Maybe our industry (especially the railroad) must rethink flexibility and people's family lives? If only I had an answer…

Back to school? No…

First, I had another rail project to tackle. And I thought Glamis was isolating… I had no idea what was to come. But that's a story for another newsletter... Until then, stay dirty!

Dirt Talk Podcast

In another installment of “Questions and Questionable Answers” with host Aaron Witt, @AaronWitt and co-host Alex Horton review questions sent in by listeners. This time, the guys answer questions like “should everyone start on a shovel before becoming an operator?”, “where does manufacturing fit into the Dirt World?” and “is it valuable to go to college for construction management?” They also discuss Aaron’s foolproof plan to track books he wants to read. It’s uh… pretty simple.

Vlog

In today's episode, we reviewed clips from famous movies that feature heavy machinery. Enjoy! #heavyequipment #construction #movies

I’ll see you next week!